I still remember the first time I opened up a broken old phone just to see what was inside. It was fascinating — a maze of circuits, tiny chips, wires — but also a bit disturbing. None of it looked recyclable. And when I learned that most of our gadgets end up in toxic e-waste dumps after they stop working, it made me think twice about how “smart” our tech really is.

Every year, we throw away over 50 million tons of electronic waste, much of which contains plastic, lead, mercury, and other materials that can take hundreds of years to break down. These discarded devices don’t just sit in landfills — they leak chemicals into our soil, air, and water. As a tech enthusiast who also cares deeply about the environment, I started asking myself: Can innovation and sustainability ever go hand-in-hand?

What happens to old gadgets? Here’s a glimpse of today’s electronic waste reality:

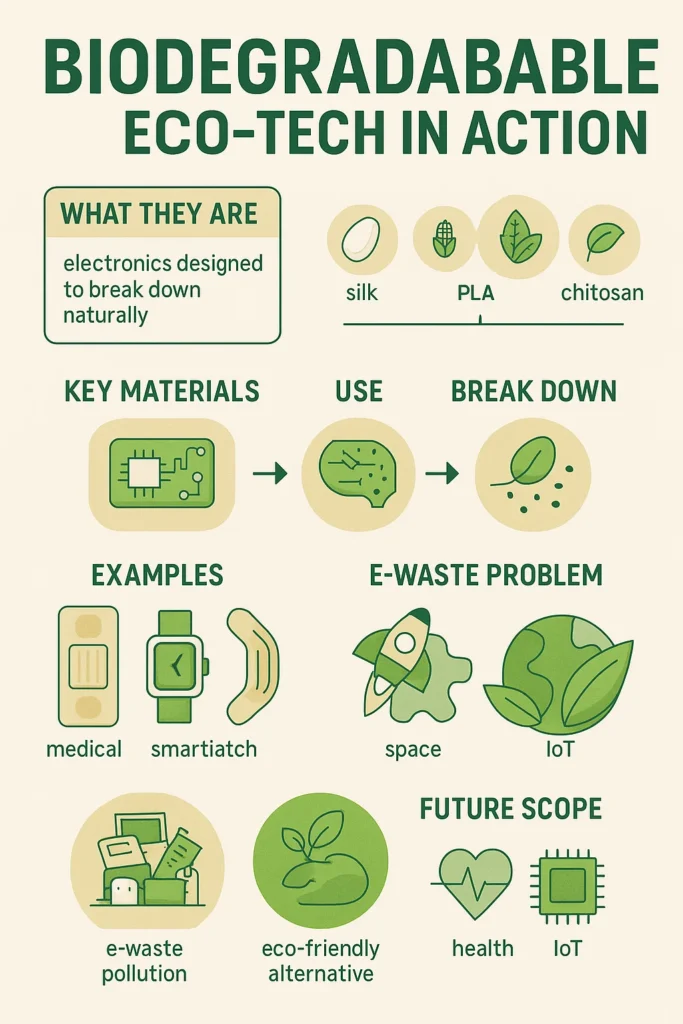

That’s when I discovered something amazing — biodegradable electronics. These are not science fiction. They are real, cutting-edge devices made from materials like silk, cellulose, and natural polymers that can dissolve, decompose, or compost without harming the planet. From medical implants that disappear inside the body to flexible, eco-friendly sensors, this is a whole new way to think about electronics.

In this guide, I’ll walk you through the world of biodegradable electronics — what they are, how they work, who’s building them, and how they just might change the way we design, use, and dispose of tech forever.

What Are Biodegradable Electronics?

At its core, biodegradable electronics are exactly what they sound like — electronic components and devices designed to naturally break down into non-toxic materials after they’ve served their purpose. Unlike traditional gadgets that persist in landfills for centuries, these electronics are made from substances that decompose through biological processes, leaving little or no harmful residue behind.

In simple terms, imagine a mobile sensor, implant, or circuit board that doesn’t need to be manually dismantled or recycled. Instead, once it’s no longer needed, it dissolves in water, breaks down in soil, or is absorbed by the human body if used internally. That’s the remarkable promise of biodegradable electronics — technology that vanishes without a trace.

These devices aren’t just limited to concept labs anymore. Researchers have successfully created biodegradable resistors, transistors, LEDs, batteries, and even entire flexible circuits using natural materials like silk proteins, cellulose nanofibers, corn starch, and magnesium. These components can be printed, stretched, worn, or implanted, depending on their use case.

So why does this matter?

- Traditional electronics use non-renewable, toxic materials like heavy metals and petrochemical-based plastics.

- Even recycling electronic waste is energy-intensive and often incomplete — a huge portion of global e-waste ends up in developing countries, causing serious health and environmental problems.

Biodegradable electronics offer a much-needed alternative. They are part of a growing movement in green technology aimed at reducing our environmental footprint without compromising innovation. They’re especially promising in short-term-use applications — like temporary medical implants, environmental monitoring devices, and smart packaging — where long-lasting hardware isn’t necessary.

In essence, these devices are built with the end in mind — not just how well they work, but also how gracefully they return to the Earth. That shift in mindset could redefine the future of how we build and discard technology.

Materials Used in Biodegradable Devices

Here are some of the most widely used biodegradable materials in sustainable electronics:

One of the most fascinating aspects of biodegradable electronics is the creative use of natural, non-toxic materials to replace traditional plastics, silicon, and heavy metals. These materials aren’t just eco-friendly — many of them are renewable, lightweight, flexible, and safe enough to be used inside the human body.

Watch this short video to visually understand how biodegradable electronics are changing the tech world:🧵 1. Silk Protein (Fibroin)

Silk, when processed into fibroin protein, can be used as a biodegradable substrate. It’s water-soluble, biocompatible, and even edible.

✅ Real-world example: Tufts University developed an implantable silk-based temperature sensor that dissolves in the body after use, eliminating the need for surgical removal.

🌿 2. Cellulose Nanofibers

Extracted from wood pulp or agricultural waste, cellulose nanofibers are lightweight, flexible, and compostable.

✅ Used in: Paper-like transistors and displays. The University of Wisconsin–Madison created biodegradable semiconductor chips using cellulose paper, ideal for eco-friendly IoT devices.

🥥 3. Chitosan

Derived from crab or shrimp shells, chitosan is biodegradable and naturally antibacterial.

✅ Used in: ETH Zurich developed a biodegradable battery using chitosan and zinc, designed for low-power disposable sensors.

🧂 4. Magnesium & Zinc

Unlike toxic heavy metals, magnesium and zinc are safe, reactive, and dissolve harmlessly.

✅ Used in: Northwestern University built biodegradable implants powered by magnesium circuits that vanish after healing.

🌽 5. Polylactic Acid (PLA)

PLA is a plant-based bioplastic made from fermented sugarcane or corn starch. It’s already used in packaging and 3D printing.

✅ Used in: Nervous System, a U.S.-based design studio, created biodegradable wearable electronics using 3D-printed PLA casings.

🌱 6. Organic Semiconductors & Natural Dyes

Organic polymers and plant-based dyes are being tested to replace toxic silicon-based semiconductors.

✅ Used in: Researchers at the University of Cambridge are using carotenoids from carrots to develop organic solar cells that can decompose after use.

🩹 7. Gelatin-Based Polymers

Derived from collagen (often sourced from animal connective tissue), gelatin-based polymers are flexible, low-cost, and ideal for temporary biomedical electronics.

✅ Used in: Korean researchers have used gelatin substrates for bioresorbable skin sensors that monitor wounds and then degrade naturally.

Many biodegradable electronics today are developed using natural polymers like chitosan, silk fibroin, and PLA, which are lightweight, flexible, and dissolve safely over time

📊 Comparison Table: Biodegradable Materials

| Material | Source | Used In | Biodegradable In |

|---|---|---|---|

| Silk Protein (Fibroin) | Silkworm cocoons | Implantable sensors, chips | Water/body |

| Cellulose Nanofibers | Wood pulp | Circuits, transistors | Soil/compost |

| Chitosan | Shrimp/crab shells | Batteries, biosensors | Soil/water |

| Magnesium & Zinc | Earth metals | Circuits, implants | Body/water |

| PLA | Corn/sugarcane | Casings, 3D-printed parts | Industrial compost |

| Organic Semiconductors | Carrots, polymers | Displays, solar cells | Moist compost |

| Gelatin Polymers | Animal collagen | Medical wearables, sensors | Body/soil |

How Biodegradable Electronics Work

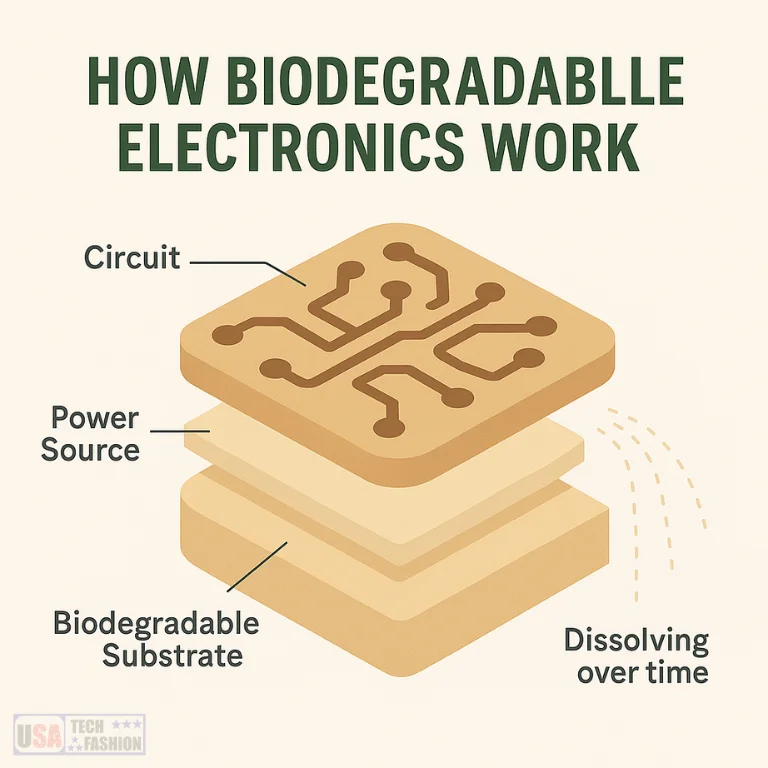

Biodegradable electronics may look like traditional devices on the outside — they can flex, light up, sense changes, or transmit signals — but the way they’re built, behave, and eventually disappear is what makes them revolutionary.

These devices are engineered with materials that break down naturally when exposed to moisture, heat, microbes, or specific environmental conditions. Some dissolve in water, others degrade in soil, and some are absorbed safely by the human body. To achieve this, scientists replace every key component of a device — from the circuit board to the battery — with materials that are both functional and transient.

Let’s break it down: The main parts of biodegradable electronics

✅ 1. Substrate (The base layer)

In regular electronics, this is usually a plastic or fiberglass board. In biodegradable electronics, it’s made of:

- Silk fibroin

- Cellulose paper

- PLA (plant-based plastic)

These materials provide flexibility and support — but also naturally decompose.

✅ 2. Conductive Traces (Where current flows)

Instead of copper or aluminum, biodegradable devices use:

- Magnesium or zinc, which oxidize and dissolve

- Carbon-based inks, derived from natural materials

These traces transmit signals just like traditional circuits — but degrade safely after use.

✅ 3. Semiconductors (The brain of the circuit)

Instead of silicon, researchers use:

- Organic semiconductors, made from plant-based polymers or dyes

- Some experimental chips even use DNA-based materials

These allow basic computing or sensing functions while being earth-safe.

✅ 4. Dielectrics (Insulators)

In place of synthetic plastics, biodegradable devices use:

- Silk

- Gelatin

- Natural waxes

These keep different circuit parts from shorting out — and they break down harmlessly.

✅ 5. Power Sources

Yes, even biodegradable batteries exist! These are made from:

- Chitosan (from shrimp shells)

- Silk and magnesium combinations

- Or even paper and saltwater for ultra-low-power applications

Once the device’s job is done — whether it’s monitoring a wound, tracking a shipment, or detecting pollution — it’s designed to disintegrate without leaving harmful waste behind. Some devices even dissolve inside the human body after being implanted, avoiding the need for surgery.

🌱 A Technology That Ends Gracefully

The beauty of biodegradable electronics isn’t just how they work — it’s how they end. Designed for temporary use, these devices align with the idea of a circular tech economy, where nothing becomes long-term waste.

This is technology that not only performs — but knows when to vanish.

Top Innovations and Real-World Examples

While biodegradable electronics might sound futuristic, they’re already making their way into medical labs, tech companies, and environmental projects around the world. Here’s a look at some of the most innovative devices and how they’re changing what’s possible in sustainable tech.

🧠 1. Dissolvable Brain Implants – Northwestern University (USA)

Researchers at Northwestern created a fully functioning biodegradable brain implant that can monitor temperature and pressure after surgery. Once it’s no longer needed, the implant dissolves inside the brain, avoiding additional surgery and reducing long-term complications. It’s made of magnesium, silicon, and silk — all materials that safely break down in the body.

💡 2. Biodegradable LEDs – Stanford & Samsung Labs

Stanford University developed organic light-emitting diodes (OLEDs) that can be printed on compostable materials. These can be used in temporary medical displays or flexible wearables. Samsung is also exploring biodegradable display layers for use in future foldable smartphones.

🌿 3. Eco-Friendly Sensors for Agriculture – Iowa State University

Engineers created biodegradable soil sensors that monitor moisture, temperature, and pH. These sensors are planted directly into farmland and degrade harmlessly after harvest — no collection or cleanup required. This is revolutionizing precision farming with zero e-waste.

💉 4. Edible Sensors – Tufts University

Tufts scientists built ingestible biodegradable sensors to monitor gut health. Made from silk and magnesium, they pass through the digestive system and dissolve naturally. These could eventually replace traditional endoscopy tools for non-invasive diagnostics.

🩹 5. Biodegradable Wound Monitors – KAIST, South Korea

KAIST researchers created a bioresorbable skin patch that tracks healing progress and body temperature. Once healing is complete, the patch dissolves into the skin, leaving no residue. This has massive potential for wound care and post-surgical monitoring.

📦 6. Smart Packaging That Disappears – PragmatIC Semiconductor (UK)

Companies are experimenting with compostable RFID tags and smart labels that track product freshness and logistics. Once a package is opened and discarded, the tech disintegrates along with the box, reducing packaging waste in e-commerce and retail.

🛠️ 7. 3D-Printed Biodegradable Wearables – Nervous System (USA)

Using polylactic acid (PLA), Nervous System has designed custom-fit biodegradable fitness wearables. These can track motion or biometrics for a short period and then be composted after use.

🌏 Innovation Is Going Global

These breakthroughs aren’t limited to elite labs. Startups in India, Germany, and Japan are also working on biodegradable sensors, batteries, and IoT devices for smart cities, logistics, and healthcare. The global push toward eco-responsible tech is turning biodegradable electronics from niche research into a fast-growing industry.

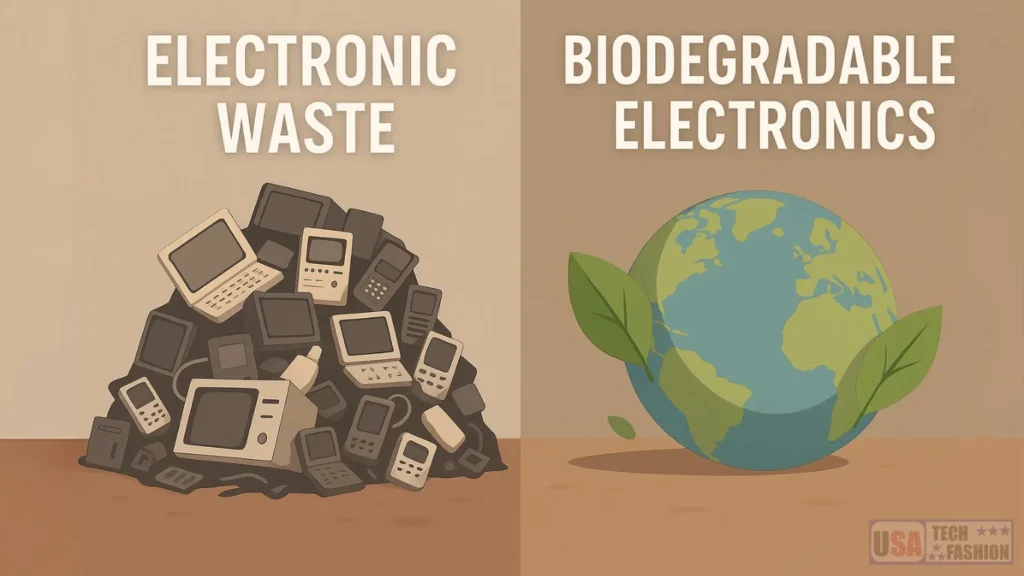

Environmental Impact and Benefits

One of the most powerful reasons for developing biodegradable electronics is the urgent need to address the global e-waste crisis. As the world becomes more digitized, we’re also generating more discarded devices — and most of them are toxic, long-lasting, and difficult to recycle.

🗑️ The E-Waste Problem

Each year, the world produces over 50 million metric tons of electronic waste, and only 17.4% is officially documented as collected and recycled. The rest is often:

- Dumped in landfills

- Burned in incinerators

- Illegally exported to developing countries, where workers dismantle it by hand — often without safety gear

These electronics leak lead, mercury, cadmium, and flame-retardant plastics into soil, groundwater, and the air, causing severe long-term harm to both the environment and human health.

According to the United Nations Global E-Waste Monitor, the world generated over 53 million metric tons of e-waste in 2019, and less than 18% was properly recycled

🌿 The Biodegradable Alternative

Biodegradable electronics are designed to vanish without polluting. Whether they dissolve in water, soil, or the human body, these devices leave behind non-toxic, natural residues — like carbon, water, and minerals.

Here are some key environmental benefits of biodegradable electronics:

✅ 1. Zero Hazardous Waste

Biodegradable materials don’t contain toxic metals or synthetic chemicals. That means no pollution when they decompose — even in unmanaged environments.

✅ 2. No Need for Recycling Infrastructure

Traditional recycling requires specialized plants, expensive sorting systems, and significant energy. Biodegradable devices can decompose on-site, eliminating the need for collection and processing.

✅ 3. Safe for Soil and Water

Imagine biodegradable sensors placed directly into the soil or water to monitor pollution — then disappearing after their job is done. That’s a reality already being tested in smart farming and marine monitoring projects.

✅ 4. Lower Carbon Footprint

Because many of the materials (like PLA, cellulose, or silk) are derived from renewable resources, their manufacturing process has a much smaller carbon footprint compared to petroleum-based plastics and rare earth mining.

In a world where sustainability is no longer optional, biodegradable electronics offer more than just innovation — they offer responsibility. They give us a way to move forward with tech without sacrificing the planet.

Challenges and Limitations of Biodegradable Electronics

As promising as biodegradable electronics sound, they’re not without real hurdles. While the technology is innovative, it’s still in its early stages — and like all early technologies, it comes with trade-offs, technical barriers, and practical limitations.

Let’s take a realistic look at what’s holding this field back from mass adoption.

⚙️ 1. Durability vs. Degradability

One of the biggest technical challenges is this:

The more biodegradable a material is, the less durable it tends to be.

Biodegradable materials are sensitive to moisture, heat, and oxygen — which is perfect when the device needs to break down, but problematic when it needs to last months or years in use. Engineers are still trying to find the sweet spot where a device is:

- Strong enough to function

- Weak enough to degrade safely afterward

💸 2. High Production Costs

Creating biodegradable electronics requires new manufacturing processes, specialized materials, and careful handling. These aren’t yet produced at scale, which means:

- Higher cost per unit

- Limited commercial availability

- Minimal supply chain support

Until production methods improve, most biodegradable devices remain lab-scale or prototype-stage only.

🧪 3. Limited Functionality

Currently, biodegradable components can perform basic sensing, powering, and display tasks — but not advanced computing or multi-layered functions like smartphones or laptops.

For example:

- You won’t find a biodegradable GPU or camera sensor yet

- Most devices are intended for short-term use (days to months)

🧍♂️ 4. Lack of Industry Standards

There are no global standards defining what qualifies as a “biodegradable electronic.” Some devices break down only under industrial composting conditions, while others need specific temperatures, microbes, or moisture levels.

This creates confusion for:

- Manufacturers

- Regulators

- Consumers

Until certifications or guidelines emerge, the industry may struggle to scale responsibly.

🚫 5. Unintended Environmental Consequences

Ironically, even natural materials can cause issues if not managed properly.

For example:

- Bioplastics like PLA can release methane in landfills without oxygen

- Gelatin-based devices may attract pests or degrade too early in humid climates

In short, biodegradable electronics are not a magic fix — but they are a necessary step toward reducing long-term waste. Like solar power or electric vehicles in their early days, this field needs time, funding, and support to grow into a reliable alternative to traditional tech.

The Future of Biodegradable Electronics

Biodegradable electronics may still be in their infancy, but their future looks incredibly promising — especially as sustainability becomes a core priority across every industry. With research accelerating and public awareness growing, we’re likely to see big shifts in how these devices are developed, used, and adopted at scale.

🔬 1. Smarter Materials on the Horizon

Scientists are experimenting with “smart biodegradables” — materials that degrade only when triggered by a specific event:

- A certain pH level in the body

- A drop in temperature

- Exposure to water or enzymes

This will help solve the current issue of uncontrolled degradation and allow for more durable, real-world applications.

🌍 2. Industrial Adoption in Key Sectors

Several industries are already testing biodegradable tech, and in the next 5–10 years we may see it rolled out in:

- Healthcare: Temporary implants, drug delivery systems, and bio-monitors

- Agriculture: Compostable field sensors, soil health trackers

- Consumer Packaging: Smart labels and indicators that vanish with the box

- Wearables: Single-use fitness or health trackers for events, races, or trials

Big companies like Samsung, IBM, and Google are already investing in sustainable tech — and biodegradable electronics are on their radar.

🏭 3. Eco-Friendly Manufacturing at Scale

As production methods improve, biodegradable electronics will become:

- Cheaper to manufacture

- More durable and efficient

- Easier to dispose of safely

Countries like Germany, Japan, and South Korea are already building pilot lines for green circuit printing, and universities are forming public-private partnerships to push this tech into the mainstream.

💡 4. Policy Support and Green Innovation Grants

Governments worldwide are rolling out “right to repair” laws, e-waste bans, and green tech subsidies. These initiatives could make biodegradable tech the new standard — especially for short-term or disposable electronics.

Just like solar energy or electric cars, biodegradable electronics may start small — but they carry the potential to change the way we build and dispose of technology forever. It’s not a trend. It’s the beginning of a smarter, cleaner future.

Conclusion:

When we think about the future of technology, we often imagine faster devices, smarter AI, or sleeker designs. But what if the most revolutionary shift isn’t about how powerful our gadgets are — but how kind they are to the planet?

Biodegradable electronics represent that shift. They’re not just about reducing waste — they’re about rethinking the entire lifecycle of technology. From dissolvable sensors to compostable chips, this field proves that innovation doesn’t have to leave a footprint.

As someone who cares deeply about both progress and the environment, I find this movement incredibly inspiring. Sure, there are challenges. But the fact that scientists, engineers, and even artists are collaborating to build tech that literally disappears when its job is done? That’s a future worth supporting.

✅ If you’re curious about eco-tech, I encourage you to keep exploring.

✅ If you’re a creator, consider sustainability in your designs.

✅ And if you’re a consumer, support companies investing in green tech.

Because the future of electronics doesn’t have to last forever — and maybe that’s the point.

Read more: Best Portable Charger with Built-In Cable: 2025 Full Buying Guide

Read more: Xiaomi Pad 6 Review: Specs, Performance, Battery & Buying Guide

Read more: The Future of Intelligent Agents in Autonomous Vehicles

Anurag Ghosh is the founder of Tech Fashion USA, a website dedicated to bringing readers the latest trends in electronics, gadgets, AI innovations, and smart tech. With a passion for simplifying complex technology, Anurag curates well-researched, easy-to-understand articles that help consumers make smarter buying decisions. Whether you’re exploring the future of wearable tech or comparing the best AI-powered gadgets, Anurag’s insights are always grounded, practical, and focused on what truly matters to everyday users. Follow his work for unbiased reviews, breaking tech news, and expert buying guides.